CO2, carbon dioxide, is an inevitable byproduct of combustion. It appears everywhere, even we humans and animals exhale CO2, not to speak about industrial processes that emit kilotons per year.

CO2 has become a global issue, threatening the existence of our species. It is a potent greenhouse gas, warming the climate and therefore messing up ecobalances that were established over thousands of years.

We therefore need technologies that contribute to lowering the CO2 amount in the atmosphere. Our mild, adsorptive approach can contribute to CO2 mitigation.

Our biggest assets are robustness towards impurities and poisons and intermittent operation. We manage to to produce methane of natural gas quality under intermittent, frequently changing feed composition switching between extremes (“gas in”, max. feed flow and “gas off”/0 feed) within minutes.

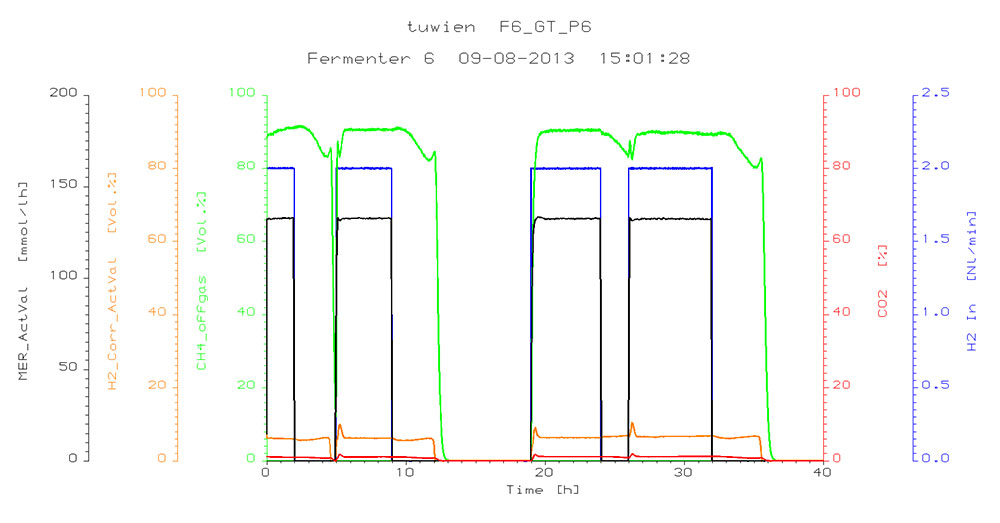

Our response from zero feed to full operational load is in the range of several minutes (see Fig. 1).

During stand-by no energy is needed (no heat, no stirring, no pumps) which minimizes operating cost (see Fig. 1).

Fig. 1 Intermittency of Krajete® Process with instant methane production and no energy consumption during transition periods in stand-by (follow the blue curve, H2, which symbolizes electrolytic H2 and therefore stored electricity and compare to black curve (methane production).

Our process is simple, robust, highly economical, selective and it highly responsive to fast operational changes. Our process is tailored to the storage of excess electricity.

Our process is therefore tailored for all applications that need intermittend operation. It combines a fast response to changing feed conditions while minimizing energy consumption in periods of transition where little/no methane is produced. It is ideally suited for instant storage of electricity as methane.

Our process can extract and convert H2 and CO2 from gas mixtures in presence of other gas components (inerts, poisons, impurities; see application 2) without gas separation and without gas purification. This massively reduces process complexity.

"Intermittency" and "selectivity" can be combined in a "power to gas“"scenario with industrially available CO2 (application 3).